service

Hotline

13829923576

7*24 hour customer service Hotline

86 13923618305

7*24 hour customer service Hotline

13928377171

7*24 hour customer service Hotline

follow

wechat

劳小姐

劳小姐

online

service

劳小姐

劳小姐

service

Hotline

13829923576

7*24 hour customer service Hotline

86 13923618305

7*24 hour customer service Hotline

13928377171

7*24 hour customer service Hotline

follow

wechat

劳小姐

劳小姐

online

service

劳小姐

劳小姐

base plastic spraying process principle and abnormal time

base plastic spraying process principle and abnormal time

1、base plastic spraying process:

1,material preparation

2. Dedusting: dedusting the plastic parts to be sprayed.

3. Loading: hang the spraying rack on the plastic parts to be sprayed.

4. Material surface wipe: mainly to clean up oil, finger marks and other manufacturers left dirty.

5. Manual dust removal: clean the dust and oil on the surface again.

6. Automatic dust removal: use electrostatic gun or brush to remove dust on the surface, and then enter the dust-free operation space

7. Primer spraying: spray primer on the surface of plastic parts, with the diameter of 1.1 and 8 guns simultaneously

8. Baking: bake the primer for 10-15 minutes at 55-65 ℃

9. Finish painting: finish painting shall be carried out immediately after the baking of primer

10. Infrared baking: 45-50 degree baking for about 5 minutes

11. UV oven baking: energy in 5000 MJ / cm2

12. Baking III: when passing through the UV furnace, baking III is not needed, but Pu needs to continue baking for about 20 minutes

13. Unloading: remove the plastic parts from the spray frame

14. FQC overall inspection: FQC carries out overall appearance inspection on spraying effect

15. Packaging:

16. OQC spot check:

17. Warehousing:

2、 Process principle and precautions:

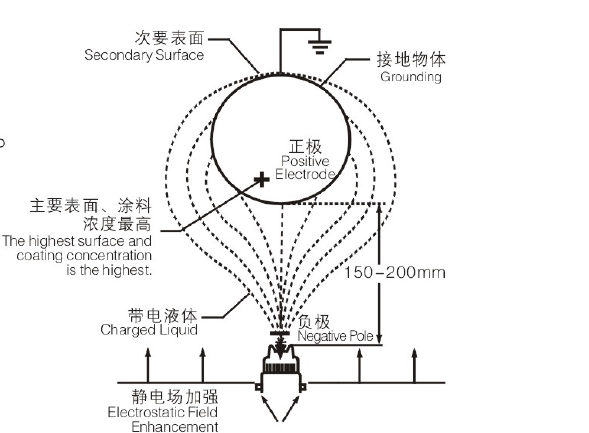

Electrostatic dedusting principle: ionize the air and the charge on the plastic products, so that the dust is in the floating state, and the air flows to take away the dust, so as to achieve dedusting and electrostatic removal

-

Note: under normal working condition, the needle of electrostatic precipitator is in blue purple flame radiation. Before working, first check whether the grounding of electrostatic generator is good? During working, do not disassemble the head of electrostatic precipitator to avoid electric shock. To check or repair, first turn off the power switch of electrostatic generator

2. Wipe: under the pressure of the operator's hand, the wipe cloth with chemical solution will take away the oil and grease from the products

Note: chemicals have limitations. Choose proper single direction running wipe according to products made of different materials and different greases

3. Spraying: when the gun needle retracts, the paint pressed to the gun head flows out of the hole of the gun. Under the blow of compressed air, the paint is blown loose and onto the product to form a film.

Precautions: the gun is too close to the workpiece, the paint cannot be atomized, the color difference is serious, and the paint is piled up. The gun is too far away from the workpiece, the paint spray is too dry, hairy, flowery and serious particles; when the primer is applied, the gun and the workpiece keep 10-15cm; the larger the atomization pressure is, the drier the paint atomization is, hairy, flowered and serious particles, the atomization pressure is proportional to the oil output, and the atomization pressure of general paint is between 0.3-0.4mpa.

4. Baking: single component catalytic paint, baking purpose is to speed up the volatilization of solvent; two component hydroxy curing paint, baking purpose is to speed up the reaction between resins and dry the paint film

Precautions: if the baking temperature is too high, the parts will be deformed due to heating; if the varnish baking temperature is too high, the internal paint will volatilize and break through the paint film, pinholes will be formed; if not, dark bubbles will be formed. Generally, the setting of baking temperature is lower than that of primer. The actual baking temperature of primer is 60 ° c-65 ° C, and that of varnish is 55 ° C-60 ° C. The temperature rise curve of the drying channel is a wide frequency sine wave. Baking time should not be too long, otherwise reduce the hardness of the paint surface

Increase brittleness; yellow paint film. The baking time is between 25-35 minutes for primer and 35-45 minutes for polyurethane varnish.

3、 Abnormal conditions:

1、 Too thick UV or too high UV energy will cause cracking.

2、 The appearance of dark leveling effect is worse than that of light leveling effect.

3、 Clogging or leaking of spray gun in spraying room can cause color difference in production batch

4、 Different parts cannot enter the spray room at the same time.

5、 At least 3kg of main agent shall be provided for each sample preparation before sample preparation

6、 The best curing distance between the spray gun and the plastic part to be sprayed is 15-20cm

7、 The lamp of UV furnace can be used for more than 1000 hours in Taiwan and 600-800 hours in Mainland

8、 The reasons for poor leveling are as follows:

1. The coating material is not good

2. Coating viscosity (9-10S is preferred)

3. Film thickness (the thicker it is, the smoother it is, the easier it is to crack and accumulate oil)

4. Leveling time, about 5 minutes

9、 UV oil thickness, full bright 12um is the best, not too thick (upper limit is 15um)

Tel:(+86)0752-2099872 (+86)13923618305(Croesus Lo) (+86)13923615305(Houq.Lian) (+86)13923616305(Mr.Lian)

E-mall: coating-sl02@hzhxl.com (Croesus.Lo) sales@hzhxl.com service@hzhxl.com

Adress:Hebei Industrial Zone,Jinxing Village,Tongqiao Town,Zhongkai High-Tech Zone,Huizhou City.

© Copyright Huizhou Huixinlong Coating Equipment Co.,Ltd. 粤ICP备15029055号